Tech News

Oxygen and copper are deliberately made into alloys, as hydrogen and sulfur purifying agents, so that both H2O and SO2 gases are formed in the melt. If the oxygen component has some control, then it will form a small bubble, under appropriate conditions, these bubbles will offset from the liquid to the solid state of the process of about 4% shrinkage. If the pores are not very large, they can be eliminated during hot pressing.

Most of the continuous casting and rolling products are equipped with non-destructive equipment, and these devices are often used online to detect surfaces such as cracks and oxides and other defects. For some high-quality applications, usually through the mechanical dressing to surface a lot of metal removed.

Most round and square copper products are produced by drawing with a conventional artificial polycrystalline die or a natural single crystal drawing die. Copper has good formability, copper rods can be easily made into relatively fine copper wire without any intermediate annealing process. Although it has this ideal, but the general practice in the magnetic wire industry during the drawing process will reduce the rate of about 90%, and then after the annealing. In addition to the rate reduction, the metallographic structure may also change, thereby weakening the copper mechanical properties. Magnetic lines are often produced by the so-called "on-line process", which involves "slow" drawing, followed by continuous annealing, while also coating. The final copper wire product is improved by reducing the reduction rate between annealings to 90%.

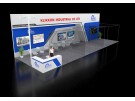

Klikkon Industry Co., Ltd is a professional manufacturer of brass machining parts, hot forging parts, brass pipings & fittings,aluminum machining parts.

We have three excellent advantages,

1,We good at producting customized products.We provide one-stop manufacturing services, including: Design,Machining, Inspection, Packaging so as to meet the needs of our customers.

2,We can provide hot forging pressure from 50 tons to 650tons

3,We will free charge to help you to make drawing or design.We will start production after you confirm the finial drawing.Our highly skilled engineers and professionals in the fields of R&D, material knowledge, deforming and machining materials, quality requirements and standards of industrial products.

4,We request a Flexible MOQ, for customer comes from young growing company, we will not request a strict high MOQ. Our vision is to grow up together with our customers.

Klikkon guarantees quality and a corresponding low price, without compromise.

Our highly skilled employees and our high-tech tools, assembly equipment and test control facilities together ensure that "Klikkon quality" delivers you perfection.

Klikkon is your reliable partner for brass products