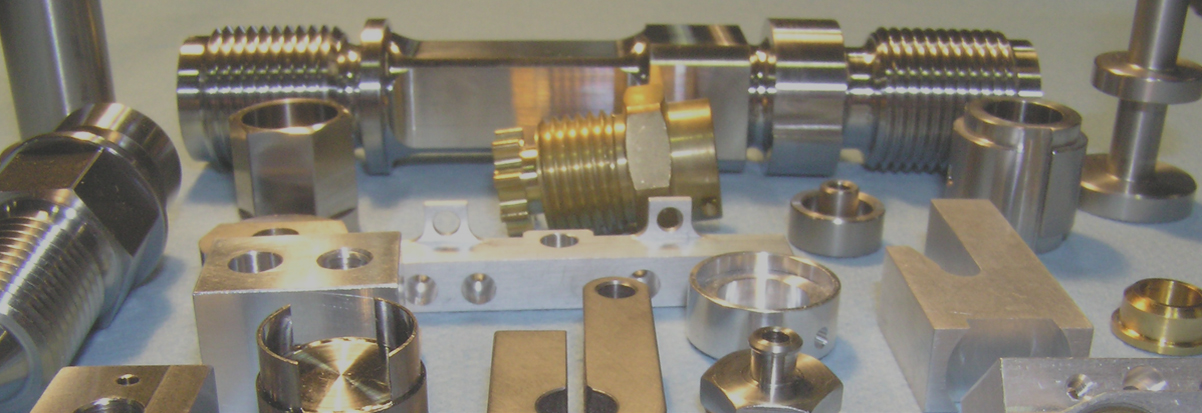

Brass Pipe Fittings

copper pipe nipple fitting(External thread )

Customized Fabrication

screw pipe fitting/din standard pipe fitting/copper pipe nipple fitting(External thread )

threaded copper pipe fittings

Klikkon Industrial are dedicated to providing innovative products and solutions, knowledgeable support and professional service to our customers that is second to none.

Price:US $0.1 - 0.25 / PieceProduct Details

Klikkon Industrial are dedicated to providing innovative products and solutions, knowledgeable support and professional service to our customers that is second to none.

screw pipe fitting/din standard pipe fitting/copper pipe nipple fitting(External thread )

threaded copper pipe fittings

copper straight male threaded aluminum tube pipe fittings

Product description

Product Performance

1. Hydraulic proof pressure test (1.5 times the maximum permissible working pressure): no leakage.

2. Dismantling and reassembly test (dismantle ten times): no leakage.

3. Vacuum test (1 × 10−4 mbar or greater): the leak rate less than 1 × 10−8.

4. Maximum static gas pressure test (with nitrogen gas to 150% of pressure rating): no visible bubbles.

5. Hydraulic impulse and vibration test (the pressure impulses at between 0.5 Hz and 1.7 Hz and the vibration at between 23 Hz and 47 Hz): no leakage.

6. Thermal cycle test (ambient to +80 °C and then to –25 °C with a hydrostatic pressure): no evidence of leakage.

7. Pneumatic pressure vibration test (The frequency of vibration shall be set at 45 Hz and complete 20 × 106 cycles): without failure

8. Fire test (in accordance with BS ISO 19921): no leakage.

9. Corrosion resistance test (the duration of exposure at least 168 h): no visible evidence of corrosion.

10. Deep water submersion test (equivalent to 3048 m of sea water): no helium detected.

11. Minimum hydrostatic pressure test (four times the maximum permissible ambient pressure rating): no leakage.

Product Features

1. Twin ferrule fittings provide metal-to-metal seal connections, non-elastomeric seals for leak-free connections.

2. Hikelok twin ferrule fittings is designed to have a maximum allowable working pressure that is higher than that of any tubing.

3. Stainless steel tube harderness: the hardness of the tube shall be not greater than 85 HRB.

4. Available in sizes from 1/16 to 2in and 2 mm to 50 mm.

5. Hikelok fittings materials include 316 stainless steel, steel, brass, aluminum, nickel-copper, Hastelloy C, 6Mo, Incoloy 625 and 825.

6. Hikelok special treated Back ferrule is to provide secure.

7. Silver coated threads to reduce galling.

8. Leak-proof joints capable of satisfying high pressure vacuum and vibration applications.

9. Industry standard design for all instrumentation grade tubing.

Klikkon products are guaranteed to provide the consistently high quality and unrivalled performance that our customers demand and our product range is manufactured with comprehensive engineering and quality assurance expertise gained over many years experience in the brass fitting market.

screw pipe fitting/din standard pipe fitting/copper pipe nipple fitting(External thread )

threaded copper pipe fittings

Our customers really do come first at Klikkon®. Don’t take our word for it - read through these comments from our customers and you’ll see for yourself from the results and feedback

screw pipe fitting/din standard pipe fitting/copper pipe nipple fitting(External thread )

threaded copper pipe fittings

Klikkon treat every customer with same, no matter customer are from small company or large, When customers are happy, we're happy.

If you have a design challenge, we’re ready. We have the expertise and capacity to take on your project challenge, whether the design is prototype-ready or still in the concept phase. For projects in the early phase, our engineers work closely with you to convert those ideas into final drawings. For projects further developed, we ensure part designs are optimized for full-scale production.

screw pipe fitting/din standard pipe fitting/copper pipe nipple fitting(External thread )

threaded copper pipe fittings

We pride ourselves on our Engineering staff. Their comprehensive understanding of the product development process, along with their creativity, enables them to often provide more effective answers than our customers originally anticipate.

Just tell us your idea, our technical will provide free technical support,

we will help you to make idea into true.

Flexibility? We’ve got it. We accommodate drawings in a variety of formats, including 3D models, hard copy schematics, or drawings rendered in Pro/E, SolidWorks and AutoCAD

WANT TO KNOW MORE?

ASK US A QUESTION

QUALITY CONTROL

*Recheck moulding before mass production

*Random quality test during production process

*Test HRC before and after heat treatment

*After surace finishing,check surface before packing one by one to ensure no defect exsist in finished products

*Inspect finished products,measure size,application test ect

Everyone loves a good story. Come check out ours.

Your good story start here.

see more Brass Pipe Fittings