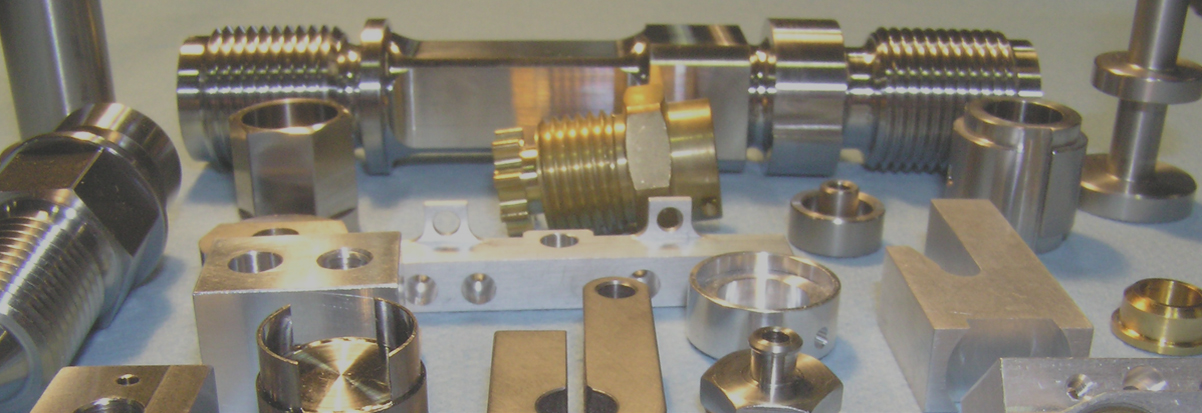

Brass Plumbing Fittings

Product Details

Klikkon Industrial are dedicated to providing innovative products and solutions, knowledgeable support and professional service to our customers that is second to none.

3/4 JIC Male/Male Brass Hose Fittings

Klikkon products are guaranteed to provide the consistently high quality and unrivalled performance that our customers demand and our product range is manufactured with comprehensive engineering and quality assurance expertise gained over many years experience in the brass fitting market.

3/4 JIC Male/Male Brass Hose Fittings

Our customers really do come first at Klikkon®. Don’t take our word for it - read through these comments from our customers and you’ll see for yourself from the results and feedback

What Klikkon can offer?

Klikkon treat every customer with same, no matter customer are from small company or large, When customers are happy, we're happy.

customized Brass Compression Tube Fitting

If you have a design challenge, we’re ready. We have the expertise and capacity to take on your project challenge, whether the design is prototype-ready or still in the concept phase. For projects in the early phase, our engineers work closely with you to convert those ideas into final drawings. For projects further developed, we ensure part designs are optimized for full-scale production.

3/4 JIC Male/Male Brass Hose Fittings

We pride ourselves on our Engineering staff. Their comprehensive understanding of the product development process, along with their creativity, enables them to often provide more effective answers than our customers originally anticipate.

China brass fitting factory Stainless steel heating oven Pipe Fittings

Just tell us your idea, our technical will provide free technical support,

we will help you to make idea into true.

Flexibility? We’ve got it. We accommodate drawings in a variety of formats, including 3D models, hard copy schematics, or drawings rendered in Pro/E, SolidWorks and AutoCAD

|

Products |

Brass Parts |

|

Material Available |

Brass |

|

Dimensions |

According to customer's drawings. |

|

Surface Treatment |

Zinc or Nickel plated, Chrome plating, polishing, anodize, black finished or as per customer's requirement. |

|

Packing |

Plastic bag, cartons, plywood cases or pallets or as per customer's requirements. |

|

Processing Equipment |

CNC machines, CNC machining center, CNC turning machine, radial drill, universal milling machine, high precision surface grinding machine, chamfering machine. |

|

Inspection Equipment |

Precision plug gauge, gauge block, digital outside misrometer, digital caliper, inside mictometer, inside dial indicator, depth vernier caliper etc. |

|

QC system |

100% during production check and randomm sampling before shipment. |

|

Tolerance |

0.02mm |

|

Business Scope |

CNC machining parts, CNC drilling, CNC turning, grinding, casting, forging, stamping, welding, sheet mental working etc. |

|

|

|

WANT TO KNOW MORE?

ASK US A QUESTION

Specification:

1.Sizes range from 1/16" to 11/2" and 2 mm to 38 mm.

2.Diverse materials and configurations are available.

3.Precision machined components ensure perfect deformation of the ferrules and tubing.

4.Female nut threads are silver-plated to minimize the friction with the body threads.

5.Radius junction design with elbows provides smooth flow path.

6.Every fitting is stamped with size, material, and heat code.

7.Fittings are easy to disconnect and retighten.

8.Hardened threads and smoothed surface finishes extend fitting life and prevent sticking of the matching threads.

FAQ

Q1. How to proceed and order?A: If the stock is available for existing valve or fittings, we will deliver them after the payment via ocean or air.

If there is a need for molding, there will be a molding charge. We will send sample to you in 15 days for your confirmation,

And then we will proceed to massive production when the deposit is made for the formal order.

Q2. What is the form of packaging for valve and fittings? Can it be customized?

A: we adopt standard export packaging. Polybag in carton box packed in pallet.

And you may need to bear the extra charge for customized packaging.

Q3. Can I choose to partially ship by air if the products are in urgent need?

A: Yes, it is one option; you may need to bear the air freight charges

Q4. When will I receive the valve after the payment?

A: It is usually 30days for production with MOQ. And there is extra shipment time that depends on which seaport to ship to, usually 15-30days for ocean shipping, and 4-7days for air shipping

QUALITY CONTROL

*Recheck moulding before mass production

*Random quality test during production process

*Test HRC before and after heat treatment

*After surace finishing,check surface before packing one by one to ensure no defect exsist in finished products

*Inspect finished products,measure size,application test ect

Everyone loves a good story. Come check out ours.

Your good story start here.