Brass Fittings

1/8"-28 Thread 45 Degreee Brass Grease Fitting

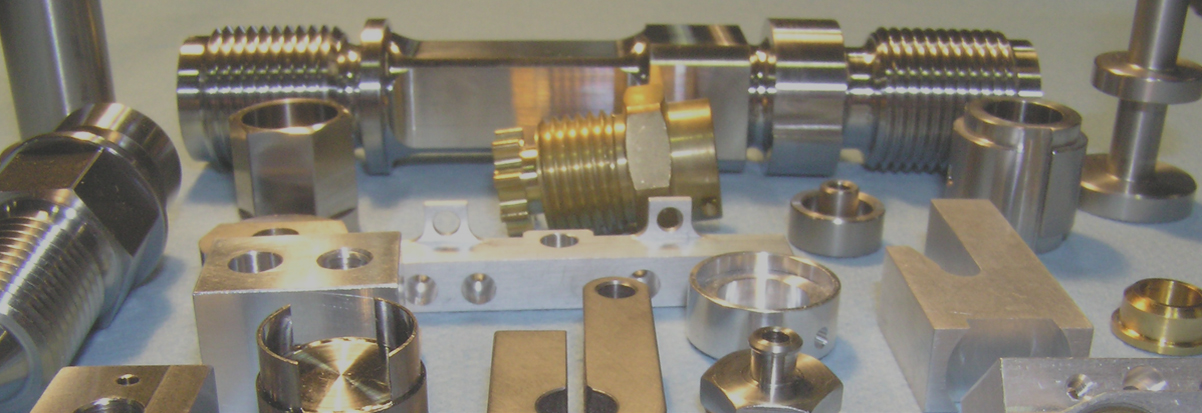

Customized Fabrication

1/8"-28 Thread 45 Degreee Brass Grease Fitting

Klikkon Industrial are dedicated to providing innovative products and solutions, knowledgeable support and professional service to our customers that is second to none.

Price:US $0.05 - 0.25 / PieceProduct Details

Klikkon Industrial are dedicated to providing innovative products and solutions, knowledgeable support and professional service to our customers that is second to none.

1/8"-28 Thread 45 Degreee Brass Grease Fitting

1. Product: 1/8"-28 Thread 45 Degreee Brass Grease Fitting;

2. Material: Carbon Steel / Mild Steel / Brass / Stainless Steel available

3. Plating: Zinc / Nickel / Chrome / Brass available

4. Thread: 3/8-24UNF standard thread

5. Usage: Autos,bearings,lathes and other machine grease lubrication fittings;

6. Price Term: FOB Ningbo Or Shanghai;CFR, CIF

7. Payment: TT, L/C

8. Leading Time: Usually within 25 to 35 days after receiving your deposit

Grease nipples are available in every possible version:

- Case Hardened Mild steel Zinc plated, stainless and brass in order to guarantee durability and safety.

- Mild steel Zinc plated to provide long lasting corrosion-proof and salt spray resistance.

- Stainless and brass grease nipples are available in most sizes.

- Specification in accordance with 71412, 3402, 3403, 3405.

- Over 70 thread types and 1200 designs straight, angled-90º, 45º hydraulic, button head and concave types.

- Self forming threads and Drive-In Shanks make installation easy because thread tapping is then no longer necessary.

- All standard grease nipples are available with no minimum quantities.

- The most enviable grease nipple range in the world.

- Protection caps-Coloured for identification.

- Custom designed parts, according to your requirements.

- We offer both metric and imperial grease nipples.

we supply grease nipple(grease fitting)

metric size: M6X1, M8X1, M8X1.25, M10X1, M10x1.25, M12X1, M12X1.25, M12X1.75, M14X1, M14X2, M16X1 .etc

inch size:1/4",G3/8",R1/8',5/16,UNF,NPT,BSP,SEA, US

the degree:30DGE,45DEG,67.5DGE.180DGE;

also we can produce as per buyer's samples or drawings.

1/8"-28 Thread 45 Degreee Brass Grease Fitting

Klikkon products are guaranteed to provide the consistently high quality and unrivalled performance that our customers demand and our product range is manufactured with comprehensive engineering and quality assurance expertise gained over many years experience in the brass fitting market.Our customers really do come first at Klikkon®. Don’t take our word for it - read through these comments from our customers and you’ll see for yourself from the results and feedback

1/8"-28 Thread 45 Degreee Brass Grease Fitting

Klikkon treat every customer with same, no matter customer are from small company or large, When customers are happy, we're happy.

If you have a design challenge, we’re ready. We have the expertise and capacity to take on your project challenge, whether the design is prototype-ready or still in the concept phase. For projects in the early phase, our engineers work closely with you to convert those ideas into final drawings. For projects further developed, we ensure part designs are optimized for full-scale production.

1/8"-28 Thread 45 Degreee Brass Grease Fitting

We pride ourselves on our Engineering staff. Their comprehensive understanding of the product development process, along with their creativity, enables them to often provide more effective answers than our customers originally anticipate.

Just tell us your idea, our technical will provide free technical support,

we will help you to make idea into true.

Flexibility? We’ve got it. We accommodate drawings in a variety of formats, including 3D models, hard copy schematics, or drawings rendered in Pro/E, SolidWorks and AutoCAD

WANT TO KNOW MORE?

ASK US A QUESTION

1/8"-28 Thread 45 Degreee Brass Grease Fitting

1/8"-28 Thread 45 Degreee Brass Grease Fitting

QUALITY CONTROL

*Recheck moulding before mass production

*Random quality test during production process

*Test HRC before and after heat treatment

*After surace finishing,check surface before packing one by one to ensure no defect exsist in finished products

*Inspect finished products,measure size,application test ect

Everyone loves a good story. Come check out ours.

Your good story start here.